ULTIVAR

A Mineral Turpentine Soluble Exterior Varnish based on carefully selected resins and UV resistant components. Colour Range: Antique (light brown) , Ebony

Learn More

Ultivar testing process

The challenge to develop the ultimate varnish and ensure its suitability for South African conditions was enormous, considering the significant amount of permutations of resins and oils, and the number of other raw materials required to yield the perfect product.

Process followed:

Initial test

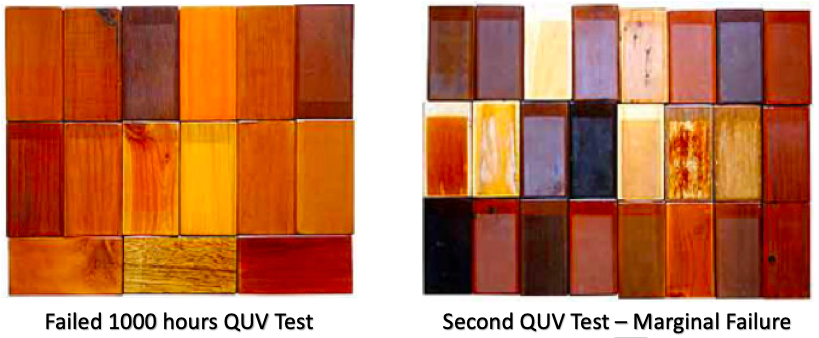

We initially produced 12 samples, based on a number of binders, and applied these to pine panels. These were subjected to very strong ultra violet light, humidity and temperature to about 40°C in a QUV Accelerated Weathering testing machine. We also obtained 13 local and imported varnishes that were exposed in the same manner. As a QUV test takes 1 000 hours (42 days) we prepared another set of panels on Meranti wood, which is denser and contains more oils and anti-oxidants.

Most locally produced varnishes failed between 300 and 800 hours. One product passed 1 000 hours on pine, but failed on Meranti, while another passed on both Pine and Meranti.

Second test

Using the binder that passed the first test, we set out to refine the formula to incorporate the other 12 components in the correct quantities to develop Ultivar. We again exposed the product to 1 000 hours of QUV and achieved excellent results.

Final test

We prepared a series of exposure panels on several Pine and Meranti products. Apart from minor discrepancies, the exterior exposure of 10 months gave similar results to that of the QUV. Further trials involved professional contractors testing for application properties, re-coating time, appearance, gloss and flow.

Following these tests, we were confident and proud to have achieved our goal of successfully developing the ultimate varnish.

Type

- A Mineral Turpentine Soluble Exterior Varnish based on carefully selected resins and UV resistant components.

Appearance

- Ultivar stains the timber and dries to a slightly less than full gloss finish with excellent slip and water-repellent properties.

Properties and Uses

- The name Ultivar is an acronym for “ultimate varnish” which it truly is. Ultivar can be used both internally and externally on all soft wood surfaces. Due to the inclusion of wood preservatives and transparent iron oxide pigments, Ultivar not only nourishes and protects the timber, but stains it to the desired colour.

Surface Preparation

- Essential for good paint performance is a substrate that has been properly cleaned and prepared. It must also be noted that moisture content should not exceed 15%.

Application Instructions

- These instructions are issued as an aid in determining correct surface preparation, mixing and application procedure and should be closely followed to obtain maximum service from the material.

1. New Uncoated Timber

- (a) Apply one coat Ultivar thinned 20% with Mineral Turpentine and allow 24 hours to dry.

- (b) Sand lightly and apply 2 further coats of Ultivar as supplied, sanding between coats and allowing a minimum drying time of 24 hours between coats.

2. Previously Varnished Timber

- (a) Remove all old varnish by either sanding or with Titanium Paint Remover.

- (b) Spot-prime bare areas with Ultivar thinned 20% with Mineral Turpentine.

- (c) Apply 2 full coats of Ultivar as supplied, allowing a minimum of 24 hours drying time and sanding lightly between coats.

Application Method : Brush.

Spreading Rate : ± 10m² per litre.

Drying Time : Surface dry 4 hours, hard dry 24 hours at 25ºC.

Cleaning of Utensils : Mineral Turpentine.

Packaging Sizes : 5 L and 1 L

Colour Range : Antique (light brown) , Ebony

Download Data Sheet